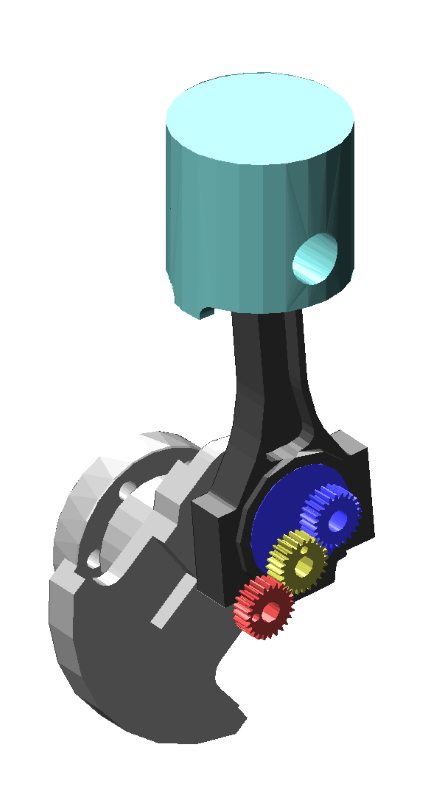

W ith a single cylinder crank drive a construction variant of the crank mechanism was simulated, which comes from the patent DE102011008747. It provides a kinematic, which enlarges the effective lever arm on the crankshaft in the ignition point and decreases during compression.

ith a single cylinder crank drive a construction variant of the crank mechanism was simulated, which comes from the patent DE102011008747. It provides a kinematic, which enlarges the effective lever arm on the crankshaft in the ignition point and decreases during compression.

For this purpose, a gear transmission is attached to the crank arm having a stationary central gear wheel. The middle and the third are rotatable mounted on the crank arm, which is additionally connected to the eccentric crank pin. This eccentricity maintains its orientation independently of the crankshaft angle.

According to the patent the dissipated torque on the crankshaft should be larger compared to the conventional crank mechanism. However, the support moment of the central gear wheel must be taken into account, in order that the torque increase is equally countervailed. The torque curve of the modified crank mechanism corresponds to that of a crossed-crank mechanism. In addition, the simulation showed that enormous forces act on the gears of the kinematic mechanism at ignition.